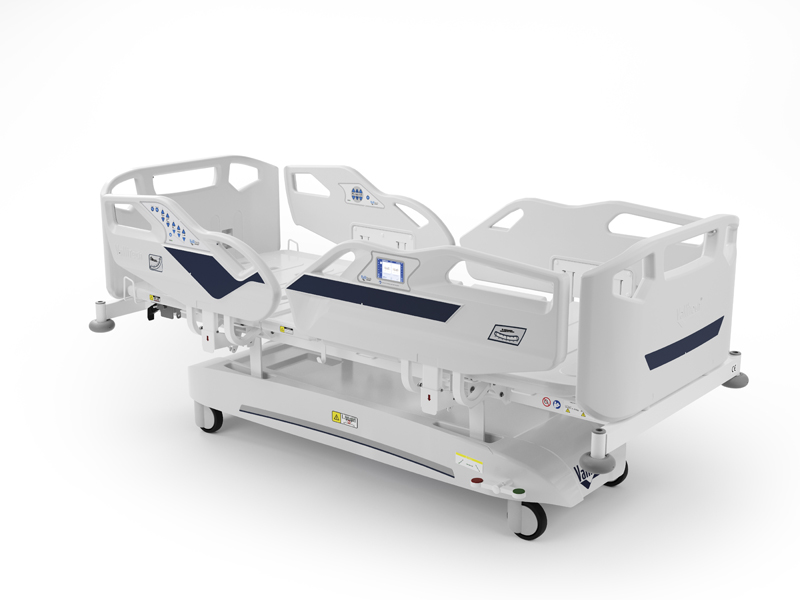

| Design. Comfort. Resistance. Durability.Vallitech beds are designed and manufactured to ensure that day-to-day use in the hospital does not cause premature and/or permanent wear to the equipment.

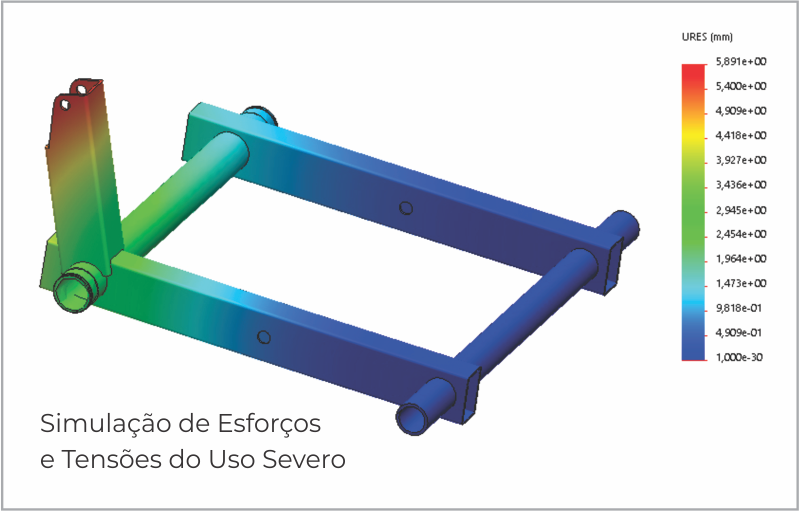

They are produced with a high quality carbon steel structure, coated with electrostatic paint and designed with the help of finite element engineering software, which simulates the stresses and strains of severe use within a hospital.

With these results, it is possible to predict and reinforce the main points of demand, giving the product a much longer service life.

They are tested exhaustively in the laboratory and at the factory to guarantee an extended service life of 10 years, without noise, vibrations or deformations. |

BASE

Made from steel tubes and coated with highly resistant thermoplastic material.

LAYOUT

Articulated, made of square steel tube, coated with high-strength thermoplastic material, removable, with high-relief modules to allow better ventilation of the mattress and side protection to prevent the mattress from sliding, and detachable for cleaning.

SHOCKSTOPS

High-impact rotary bumpers made of polyethylene, located at the four corners of the bed ("Roller Bumpers").

HEADBOARD AND FOOTBOARD

Removable, blown in high-density polyethylene.

SIDE GUARD RAILS

Articulated, blown in high-density polyethylene, with an unlocking mechanism and movement towards the side of the bed, injected in carbon steel, allowing the bed to be lowered, facilitating patient transfer and avoiding problems with probed patients. Reduced space between rails, just 160 mm, which prevents patients from falling.

MOVEMENTS

They are driven by electric motors and controlled via membrane keypads built into the railings (internal and external) and the top of the bed. The membranes in the rails can be used to control the fowler's movements of the legs and back, the elevation of the height, the night light (internal side), the nurse call (optional), the armchair position (external side) and the self-contouring (external side). All the bed's movements can be controlled from the top of the footboard, including trendelemburg, reverse trendelemburg and locking the rail controls. This intelligent system has a microcontrolled board that performs the pre-programmed movements at the touch of a button.

Self-leveling feature when lifting, which ensures that if the bed is tilted, the motor positioned higher up will wait until the bed is completely level and then continue lifting evenly.

WHEELS

It has 5" diameter wheels and a central brake system with a directional wheel, activated by a pedal.

PAINTING

Electrostatic powder coating, with anti-corrosion efficiency through phosphating.

IV STAND (OPTIONAL)

Telescopic, stainless steel, built into the underside of the bed. Side hooks for bags.

CONNECTIVITY (OPTIONAL)

The connectivity system has been developed for remote monitoring of the bed directly at the nursing station.

With the help of sensors, protocols were pre-set directly on the bed processor, allowing for better control in reducing patient falls, care times, nursing calls, patient positioning in bed, degree of back inclination due to lung problems and decubitus change intervals in order to provide greater comfort and avoid complications due to prolonged immobility, such as: decompressing areas of bony prominences, preventing lung complications and pressure ulcers and stimulating circulation.

When the protocols are activated, the bed monitors their functions and if any changes are detected, an audible alarm in the bed and a pop-up on the monitoring screen in the nurse will be initiated.

Points monitored: rails, brakes, bed height, presence of patient in bed, patient lying or sitting, weight, back inclination and decubitus change time.

GRAPHICAL INTERFACE

GRAPHICAL INTERFACE

An LCM (liquid crystal module) display built into the grid, with special graphic controllers, in color and with touchscreen interaction, supports the graphic interface. Operation is intuitive, making it easy for caregivers and the Clinical Engineering team to visualize the bed's status.

It offers visualizations of patient information, such as back angle, trendelenburg and reverse, and activation of medical care protocols. Any changes detected will trigger an audible alarm in the bed and a pop-up will be shown on the display indicating which protocol has been activated.

On beds with integrated scales, a history of the patient's stored weights, BMI (body mass index) calculation, zeroing and tare of the scale will be shown on the display.

The maintenance status of the bed can be monitored via the Clinical Engineering screens, which provide information such as battery voltage and charge level, limits, currents, overloads, usage time, the ageing factor of each of the motors and the status of each of the bed's sensors.

PATIENT SAFETY

COMPLIANCE WITH IEC 60601-2-52

High-density polyethylene hinged side protection rails, certified to the new ABNT NBR IEC 60601-2-52:2013 standard, which standardizes patient safety measures such as: minimum rail height of 220 mm (above the mattress) covering more than 50% of the bed, spacing of less than 60 mm between the side rails and between the headboard/sideboard and the side rails, openings built into the rails/headboard/sideboard smaller than 120 mm and other spacing to avoid trapping the neck, chest and head. It has a mechanism for unlocking and moving the bed sideways, allowing it to be lowered into the bed, facilitating patient transfer and avoiding problems with probed patients.

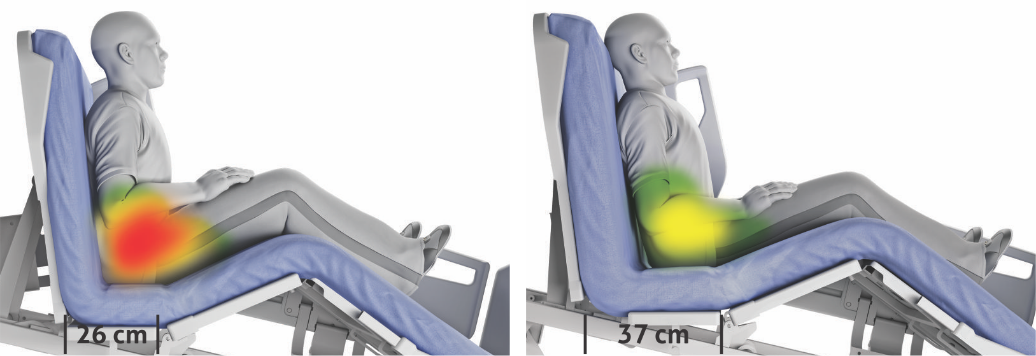

ABDOMINAL COMPENSATION SYSTEM

Abdominal compensation system designed to reduce pressure on the patient's abdomen, where a 110 mm offset in the back is made during movement. Standard system for G-021 rails.

LAYOUT | HEAD |

|  |

| OPTIONAL: ABS bed: thermoformed ABS cover with ventilation and side flaps for the mattress. G-21 grid standard. | Headboard C-031. Optional: gray sticker. |

GRID CONTROL AND SUPERVISOR | |

| |

| Grid and Supervisor Control (Optional): allows you to control grid locks and bed functions in the supervisor position. | |

CLEANING | POSTURE |

|  |

| Easy and immediate access for maintenance, cleaning and disinfection tasks (optional thermoplastic bed). | |

WeAssist

Movimentar camas nunca foi tão fácil

WeAssist™ é uma tecnologia inteligente e intuitiva para rodas, especialmente desenvolvida para facilitar a rotina hospitalar, tornando o deslocamento de camas com o paciente muito mais simples, seguro e eficiente.

A cama se move automaticamente junto com o condutor, graças a um software baseado em algoritmos e ao rodízio WeAssist™, que torna simples iniciar, virar e parar a cama ao empurrar ou puxar. O movimento é detectado pelo software e refletido pelo rodízio, que imediatamente auxilia nos movimentos com base na inclinação, declive, força de empuxo e peso.

O We Assist™ não só apoia os profissionais no trabalho, mas também protege a sua saúde. Chegou a hora de cuidar melhor dos profissionais que cuidam de todos nós.